Floor Marking for Lean Manufacturing: Optimising Efficiency and Workflow

PermaStripe

In the world of manufacturing, efficiency is critical. Lean manufacturing principles focus on minimising waste and maximising productivity, and one often overlooked aspect of this approach is floor marking. Floor marking plays a crucial role in implementing lean principles within manufacturing facilities by providing visual organisation, enhancing safety, and optimising workflow.

Benefits of Floor Marking in Lean Manufacturing

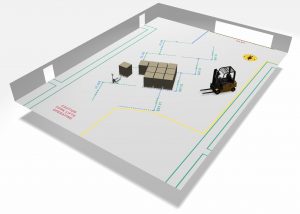

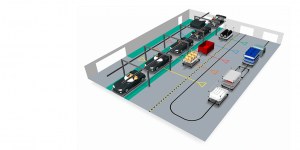

Floor marking in lean manufacturing offers numerous advantages, primarily centred around visual organisation, safety enhancement, and workflow optimisation. Through strategically placed markings, manufacturing facilities can visually guide employees, facilitating efficient navigation within the workspace. For instance, colour-coded markings can designate different zones or processes, aiding employees in locating materials and equipment promptly.

Additionally, floor markings enhance safety within the manufacturing environment. They delineate walkways, hazardous areas, and emergency exits, reducing the risk of accidents and injuries. Studies have shown that proper floor markings can significantly reduce the number of workplace accidents, making it a crucial component of any safety program.

Another notable benefit is the optimisation of workflow. By indicating designated areas for materials, equipment, or finished products, floor markings streamline operations, minimising time wastage. This streamlined workflow leads to heightened productivity and shorter lead times, ultimately bolstering overall efficiency.

Supporting Lean Manufacturing Principles

Floor marking aligns closely with lean manufacturing principles, particularly the 5S methodology and visual management. The 5S methodology, emphasising organisation and standardisation, finds implementation through floor markings, which visually segregate and standardise work areas, promoting order and cleanliness.

Moreover, floor marking supports visual management, a key aspect of lean manufacturing that involves using visual cues to communicate information effectively. Floor markings serve as visual indicators of workflow, safety guidelines, and organisational structure, enabling employees to quickly understand and adhere to established processes.

Effective Floor Marking Strategies

To maximise the benefits of floor marking, facilities can employ various strategies. Colour-coded markings, for example, distinguish different materials or processes, reducing errors and enhancing efficiency. Clear pathways for materials or equipment can be created, minimising unnecessary movement and optimising workflow.

Furthermore, facilities can use floor markings to indicate storage locations for materials, tools, or finished products, making it easier for employees to locate and retrieve items as needed. By optimising the layout of the workspace with strategic floor markings, facilities can minimise waste, improve productivity, and enhance overall efficiency.

Floor marking is a critical component of lean manufacturing, providing visual organisation, enhancing safety, and optimising workflow within manufacturing facilities. By aligning with lean manufacturing principles such as the 5S methodology and visual management, floor marking supports initiatives to minimise waste and maximise efficiency. For expert guidance on floor marking solutions tailored to your specific needs, contact PermaStripe today.